Table Of Content

- How do cruise ship propellers work?

- TradeWinds Debuts 59-foot TWe6 Smart Electric Yacht

- © Copyright 2024. Orbitshub. All Rights Reserved Design by Elatre

- Latest Marine Technology Articles You Would Like:

- How do cruise ships avoid hitting things with all those propellers?

- Gas-turbine cruise ship power system

With the pod system where the propeller is found in the front of its pod, it is turning in water that has been undisturbed. This allows the pod to be 5%-6% more efficient due to improved water flow. Cruise ship propellers can cause harm to marine life if not designed and maintained correctly. Proper propeller design and maintenance can help reduce the risk of damage to marine life. Cruise ship propellers, just like any propeller used on a modern ship, are made from an alloy of stainless steel and aluminium. This provides the necessary strength to be able to move through the water, and it is resistant to rust, too.

How do cruise ship propellers work?

The transmission determines propeller revolution like the transmission in an engine transfers RPM to a manageable speed to power the rear wheels in a car. In summary, if you are sensible on a ship or near a cruise ship, you shouldn’t have anything to worry about. But don’t take risks if you see a cruise ship in port and fancy getting a closer, water-level view.

Boat that Cameron Robbins jumped off was a model pirate ship - New York Post

Boat that Cameron Robbins jumped off was a model pirate ship.

Posted: Wed, 31 May 2023 07:00:00 GMT [source]

TradeWinds Debuts 59-foot TWe6 Smart Electric Yacht

Divers Nearly Caught In Cruise Ship Propeller -VIDEO - gCaptain

Divers Nearly Caught In Cruise Ship Propeller -VIDEO.

Posted: Fri, 23 Oct 2015 07:00:00 GMT [source]

All these ships were constructed by the German shipbuilder MV Werften. Currently, almost 2/3 of all large-sized cruise vessels, icebreaking ships, and high ice-class cargo ships are with Azipod propulsion. Cruise ship propellers are an essential part of these massive vessels. They allow cruise ships to travel across the oceans, carrying thousands of passengers to their destinations. From the traditional fixed-pitch propellers to the modern azipods, cruise ship propellers have come a long way in terms of design and functionality. These propellers must be strong enough to withstand the forces of the sea, while also being flexible enough to provide the necessary maneuverability for the ship.

© Copyright 2024. Orbitshub. All Rights Reserved Design by Elatre

Cruise ship propellers act as the beating heart of a ship, but their impact extends beyond. The underwater noise can harm marine life, affecting their communication and migration patterns. Propeller maintenance is an ongoing process that involves regular inspections, cleaning, and repairs. The blades must be checked for cracks, erosion, and other forms of damage. Any damage found must be repaired promptly to prevent further damage. Gearing allows an engine to move at a more efficient and faster speed.

We describe not only the cruise ship propeller size, but also how it integrates with the rest of the engine. The mechanics of cruise ship propellers are a fascinating blend of physics, hydrodynamics, and engineering. Through precision design and careful calibration, these propellers efficiently convert engine power into forward motion, allowing cruise ships to glide through the water with grace and power. Propellers consist of multiple curved blades, shaped like airfoil profiles, attached to a central hub.

Since the propeller rotates through water at an angle, a suction and pressure side exist on each of the propeller blades. The faster a blade slices through water, the lower the pressure becomes with the suction side. Cruise ship propellers require regular maintenance, including cleaning, polishing, and repairing any damage or wear.

How do cruise ships avoid hitting things with all those propellers?

One to accommodate on set of circumstances and the other to perform best under the different load. It could, in fact, be that more that one propeller will be suitable for your boat and motor combination depending on your usage. It is imperative, however, that the wide open throttle RPM fall within the range specified by your engine manufacturer. Switching form an uncupped to a cupped propeller will also reduce your RPM. The cupped propeller of the same pitch and diameter will typically reduce your RPM by approximately 200.

In addition to providing forward thrust, cruise ship propellers also contribute to the ship’s maneuverability. By adjusting the pitch of the blades or changing their rotation direction, the ship’s captain can control the ship’s turning radius and maneuver in tight spaces. Water conditions and operating environment also play a crucial role in propeller size selection.

Consult your owner's manual for the appropriate prop size and pitch for your boat's engine. When it comes to understanding how fast a boat propeller spins, several factors come into play. Dive into our article and navigate the waters of boat engine RPM effortlessly. The idea of electromagnetic thrusters was first patented in the United States by Rice during 1961. After this invention, the United States took an important role in theoretical and experimental studies, which led to the Westinghouse Research Laboratory report in 1966.

The criticality of this thermal condition can be seen from the figure below, which shows how the resistance of a superconductor changes with temperature and eventually reaches a critical temperature. Superconductors are also sensitive to current and magnetic fields, which if too high, the superconductor it will be ruined. But first, let’s take a moment to appreciate the intricate mechanics and functionality of these immense propellers before delving further into their size and construction.

Depending on the manufacturer, these blades typically are pitched in a way that propels the boat forward or backward when the transmission is engaged. The term “pitch” refers to how far forward or reverse a propeller will theoretically travel through a solid material (picture a screw twisting into a wood block). For example, a prop with a 12-inch pitch will theoretically move through 1 foot of solid material with each full rotation.

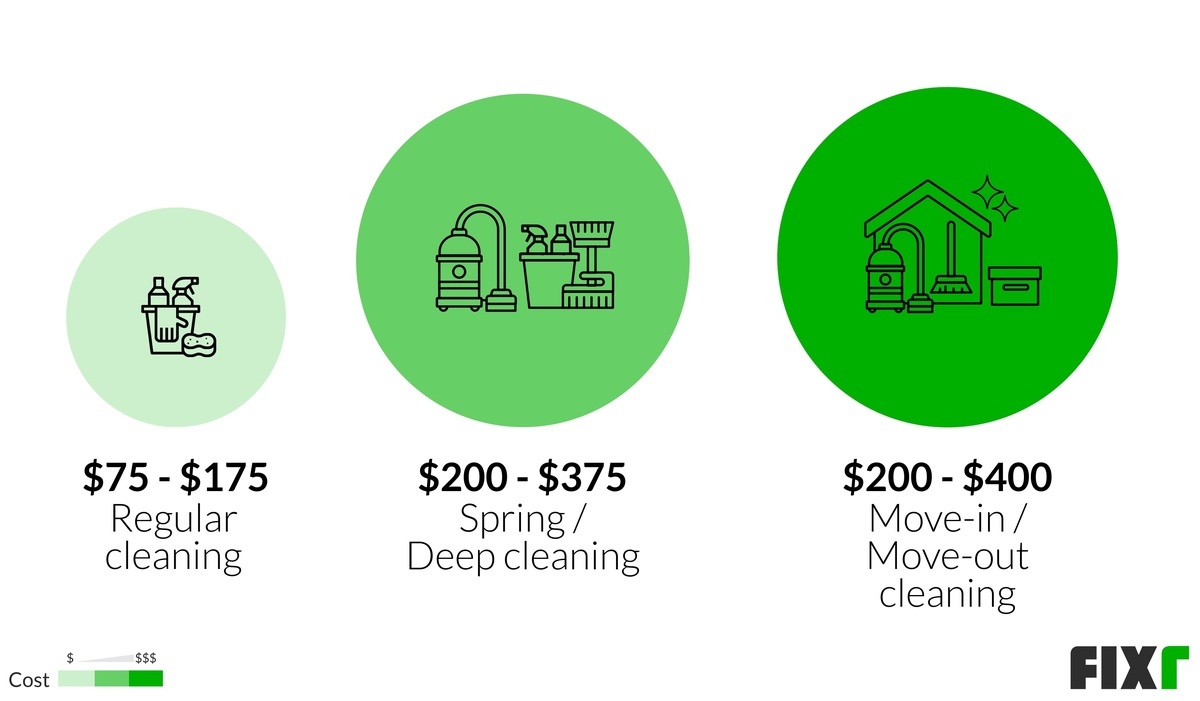

A cruise ship propeller can cost anywhere from $1 million to $10 million. The cost of a propeller depends on a number of factors, including the size of the propeller, the type of material it is made of, and the operating conditions of the ship. If a cruise ship propeller breaks, it can have a significant impact on the ship’s performance.

An ABB Azipod system has a large impact on the operating efficiency of a cruise ship. It effectively reduces bad emissions and energy consumption by 20%. This propulsion system resides in the ship’s aft outside of the hull.

The Promas Lite propulsion future clients, besides passenger ships, are marine vessels like fishing and freighter ships. Probably you've heard about Carnival cruise ship accidents related to power failures in 2013. The maneuverability of a cruise ship is another important factor that determines the size of its propeller. The more maneuverable the ship needs to be, the larger the propeller needs to be in order to provide the necessary turning force.

Each propeller was powered by a separate engine, creating a total power of 30,000 hp. It has been argued that the Titanic’s propellers were the largest ever to be built. This container vessel contains probably one of the largest ship propellers ever built. The six-bladed propeller is about 9.1 meters in diameter and weighs 101.5 tons. Justifiably so, it is the largest ship propeller ever built, providing the ship maximum speed of 27 knots.

No comments:

Post a Comment